Mid-West Model 220 Piston Type Differential Pressure Switch

Transmitter 316L Stainless Steel Body

Hazardous Locations Certified

220SC-02-O-JAA

4,000 PSIG working pressure (3,000 PSIG SWP for ATEX units), 316L stainless steel wetted pressure-containing body assembly, stainless steel piston and ceramic moving internals, ceramic magnet, Buna‑N seals (other elastomers available), ¼” FNPT end connections (½” optional), engineered plastic dial case with shatter‑resistant acrylic lens, 4½” round dial. Accuracy ±3/2/3% full scale (ascending). Optional loop‑powered 4–20 mA transmitter and hermetically sealed switch outputs. CSA, UL and ATEX/IECEx certifications for hazardous locations. Five year limited warranty.

Other Body Materials: Special order required for alternate materials; contact CMC.

4,000 PSIG working pressure (3,000 PSIG SWP for ATEX units), 316L stainless steel wetted pressure-containing body assembly, stainless steel piston and ceramic moving internals, ceramic magnet, Buna‑N seals (other elastomers available), ¼” FNPT end connections (½” optional), engineered plastic dial case with shatter‑resistant acrylic lens, 4½” round dial. Accuracy ±3/2/3% full scale (ascending). Optional loop‑powered 4–20 mA transmitter and hermetically sealed switch outputs. CSA, UL and ATEX/IECEx certifications for hazardous locations. Five year limited warranty.

Other Body Materials: Special order required for alternate materials; contact CMC.

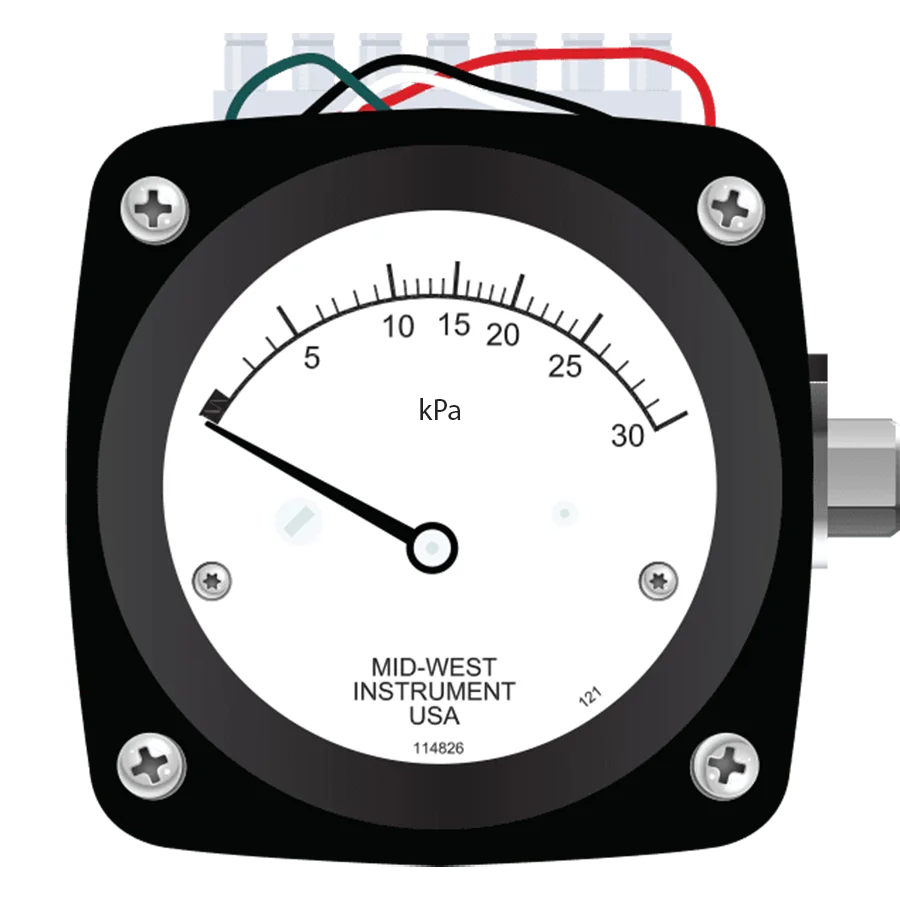

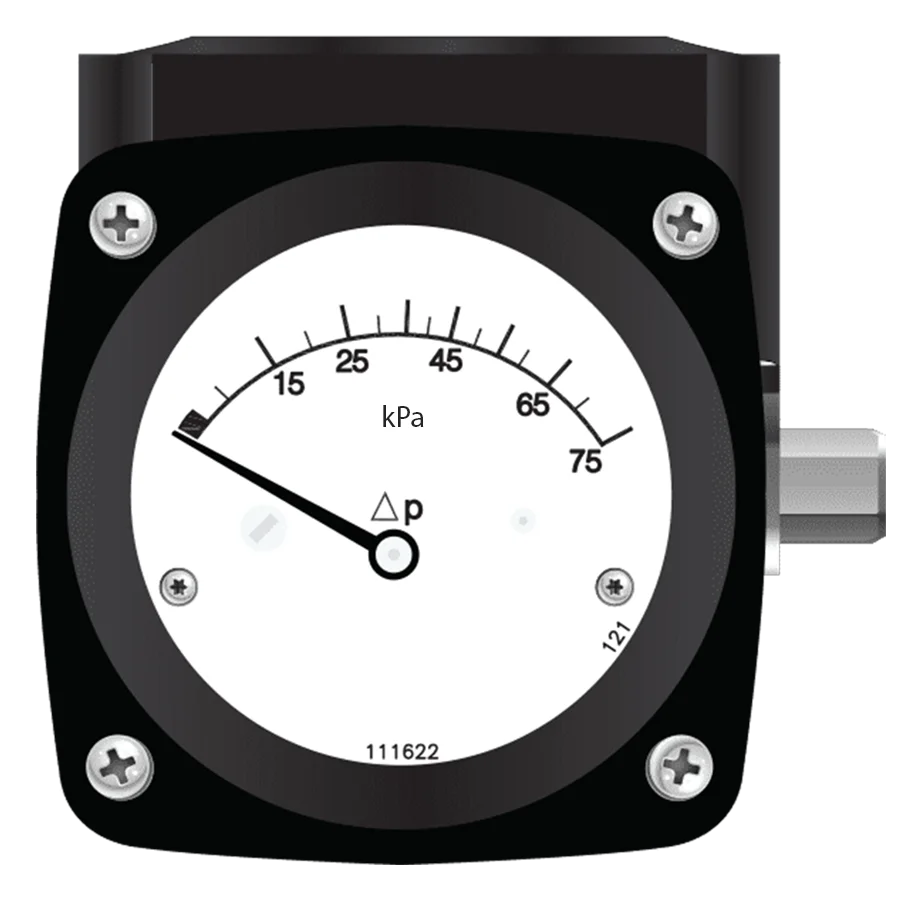

Model 220 4.5 Inch Dial

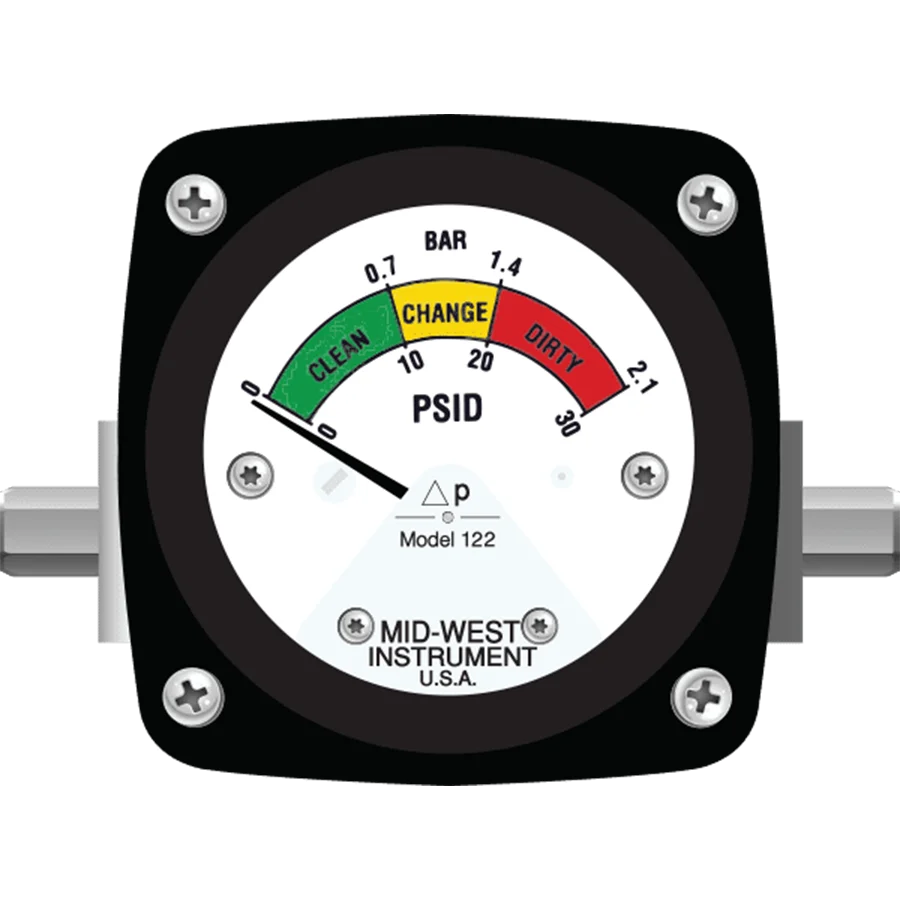

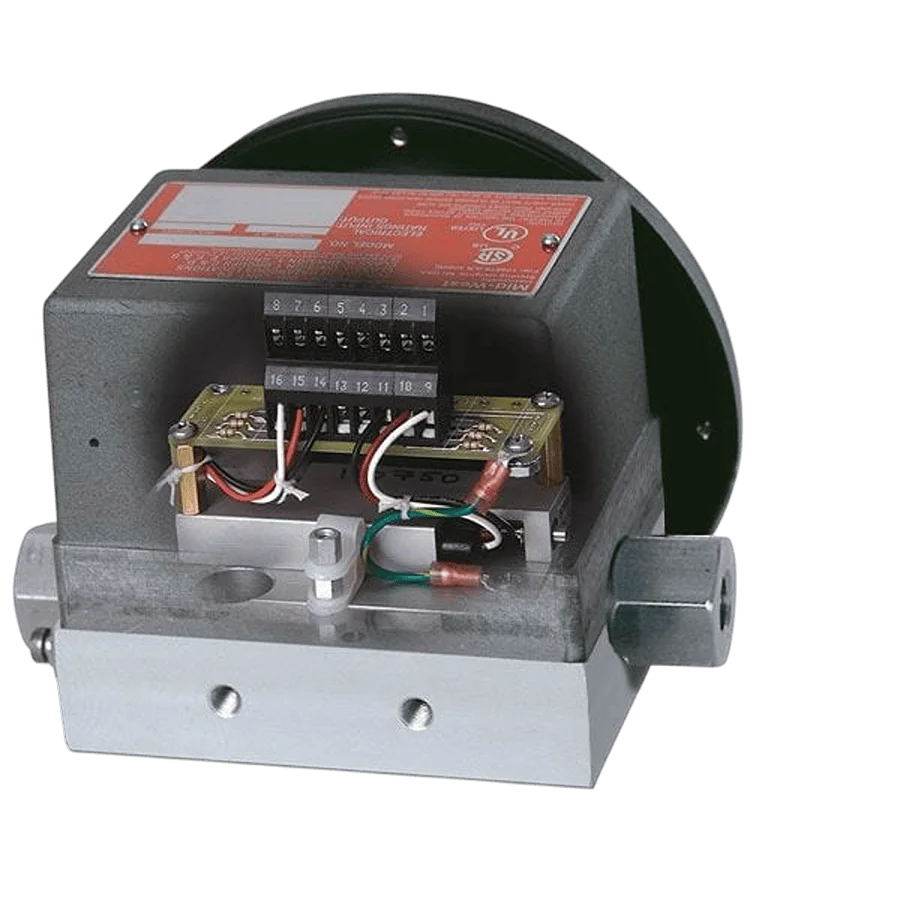

Model 220 Electrical Switch

Product Features and Benefits

- Low cost, rugged piston type differential device for measuring and controlling pressure drop across filters, strainers, separators, valves and pumps.

- Simple, compact piston design with precision‑sized piston and bore; magnetically coupled stainless steel/ceramic internals for reliable differential measurement.

- High working pressure: 4,000 PSIG (275 bar) standard; ATEX/IECEx rated units 3,000 PSIG SWP. Proof pressure up to 8,000 PSIG (transmitter 6,000 PSIG); roof pressure 16,000 PSIG.

- Over‑range protection to maximum pressure; piston‑to‑bore leakage guaranteed ≤15 SCFH air at 100 PSID (ambient).

- Weather resistant construction as standard with shatter‑resistant acrylic lens; anodised aluminium dial case available.

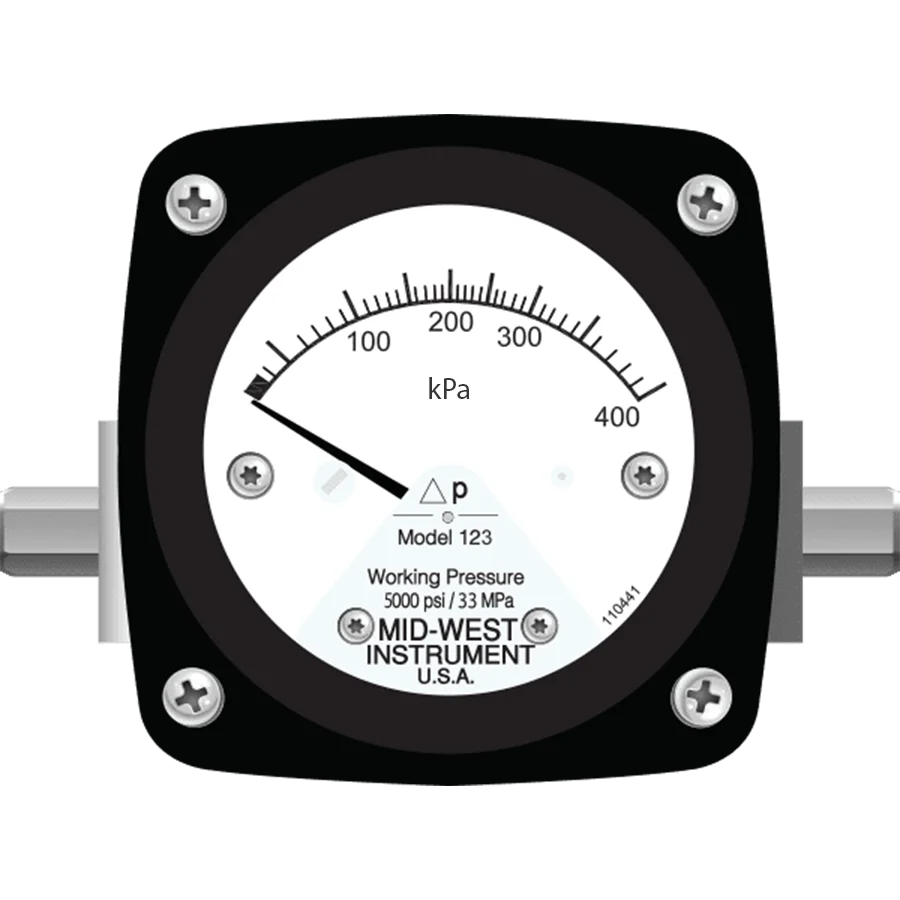

- Standard dial: 4½” round; multiple scale options in PSID, kPa and bar, plus dual scale combinations for flexible field use.

- Built‑for‑site control: one or two hermetically sealed reed switches (SPST/SPDT) with independent adjustable set points, optional DPDT relay outputs (up to 10 A), and field‑wireable terminal strip.

- Loop‑powered 4–20 mA transmitter option (8–28 Vdc loop power) with local display; each transmitter individually calibrated using 11‑point linearisation.

- Explosion‑proof electrical enclosure and ½” FNPT conduit interface; factory third‑party certified for Class I/II Division 1 and Division 2 hazardous locations and ATEX/IECEx Ex db h IIB + H2 / Ex tb IIIC.

- Operating temperature ranges and limits depend on electrical options — see specifications for exact limits.

- Gauge body and internal components are wetted parts.

DP Range And Accuracy

DP Range: 0–5 PSID to 0–100 PSID (0–0.35 bar to 0–7.0 bar). Extended/custom ranges available on request.

- Accuracy: Differential gauge accuracy ±3/2/3% full scale (ascending). Transmitter option accuracy typically 2% FSR (upper 80% of full scale).

- Leakage: Bore leakage across piston not to exceed 15 SCFH air at 100 PSID (ambient); transmitter variants rated with maximum leakage 32 SCFH @ 100 PSID.

- Standard dial ranges include 0–5, 0–10, 0–15, 0–20, 0–25, 0–30, 0–50, 0–60, 0–75 and 0–100 PSID with corresponding kPa/bar dual scales.

Model 220

Model 220 Switch

Common Applications

- Filter and strainer differential monitoring and control

- Separator and valve differential monitoring

- Pump and chiller protection

- Local flow indication and alarm/trip functions

- Hazardous area installations in petrochemical, power, HVAC and water treatment plants

Standard Materials & Connections

- Body: 316/316L stainless steel wetted pressure containing assembly

- Wetted internals: stainless steel piston with ceramic moving components and ceramic magnet

- Seals: Buna‑N standard; Viton®, Neoprene, Ethylene Propylene and perfluoroelastomers available

- Process connections: ¼” FNPT standard (½” FNPT optional)

- Dial case: engineered plastic standard; anodised aluminium option

- Lens: shatter‑resistant acrylic standard; shatter‑proof glass optional (consult factory for compatibility with liquid fill)

Additional Options

- Alternate dial sizes and custom scales, multiple scale dials and special decals

- Anodised aluminium dial case, 6” dial option

- Liquid fill (consult for lens compatibility) and maximum indicator follower pointer

- Oxygen cleaning, stainless steel tags, pipe mounting kits (carbon steel or stainless)

- Reversed high/low process connections (not available with certain electrical or transmitter options)

- Custom un‑coded options for tailored configurations

Standards & Certifications

- ASME B1.20.1; ASME B40.100; NEMA Std. No. 250; SAE J514

- CSA C22.2 No. 14, 25 and 30; UL Std. No. 50, 508, 698 and 1203

- EN60079‑0, EN60079‑1, EN60079‑31; IECEx and ATEX Ex db h IIB + H2 Ex tb IIIC IP65 (3000 PSIG SWP)

- NACE MR0175 where specified

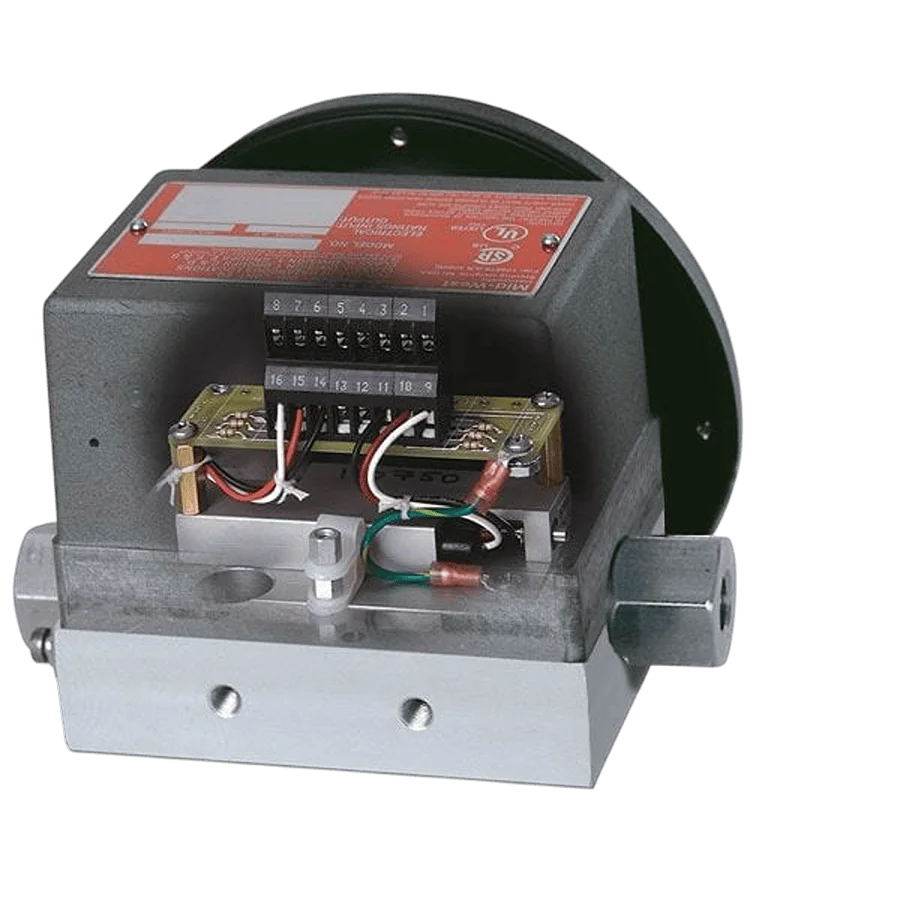

Model 220 Rear View

Additional Services

Custom Dial Face

Personalised dial faces tailored to your specifications.

Tagging Service

Services include stainless steel tags with wire or screw options.

Calibration Report

Calibration and accuracy certification from Mid-West or CMC.

Modification Service

Modification of existing stock units to for specific dial and electrical requirements.