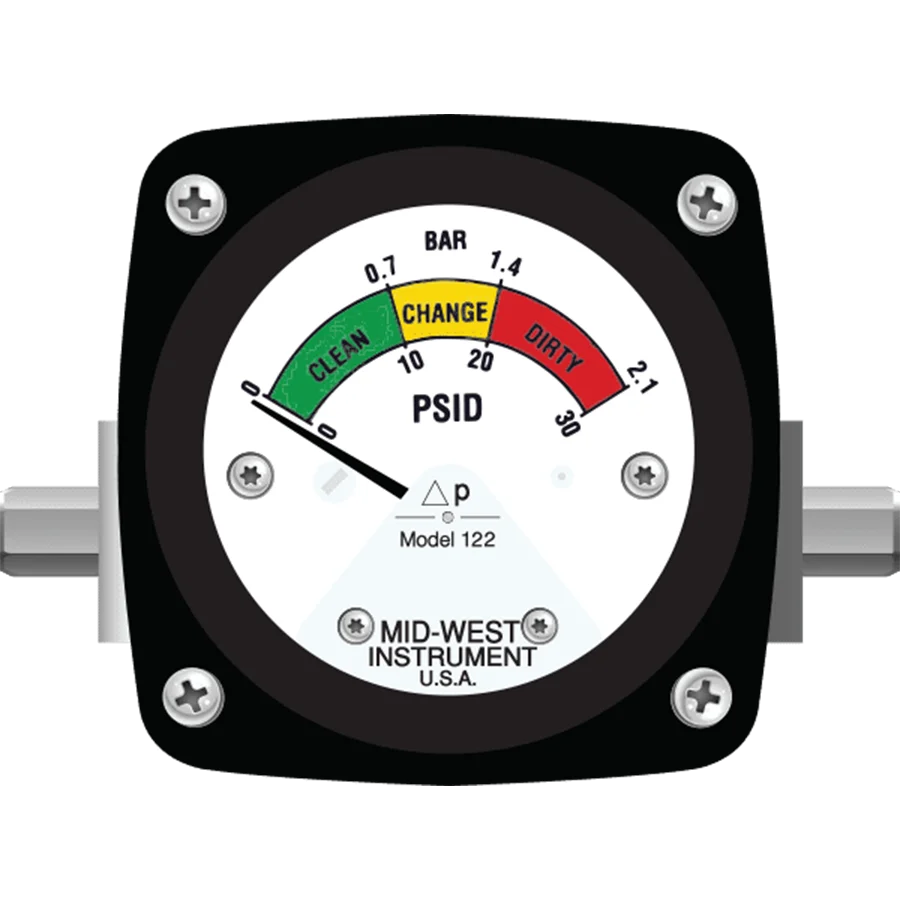

Mid West Model 122 Piston Type Differential Pressure Gauge

Aluminium Body

122-AA-02-OO

3,000 PSIG Working Pressure, aluminum body, 316 stainless steel piston, ceramic magnet, Buna-N seals, ¼” FNPT end connections, engineered plastic dial case with shatter-resistant acrylic lens, 2½” round dial. Accuracy ±5% full scale (ascending).

Other Body Material: Brass and stainless steel available, special order, contact CMC.

3,000 PSIG Working Pressure, aluminum body, 316 stainless steel piston, ceramic magnet, Buna-N seals, ¼” FNPT end connections, engineered plastic dial case with shatter-resistant acrylic lens, 2½” round dial. Accuracy ±5% full scale (ascending).

Other Body Material: Brass and stainless steel available, special order, contact CMC.

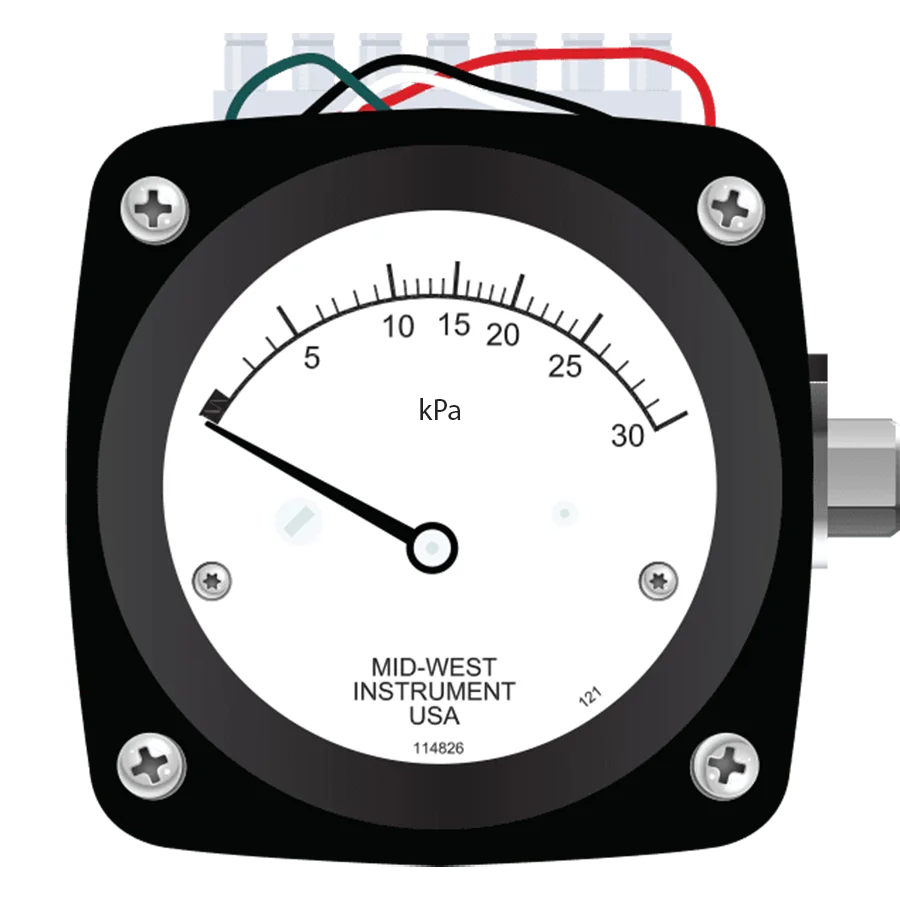

Model 122 2.5 Inch Dial

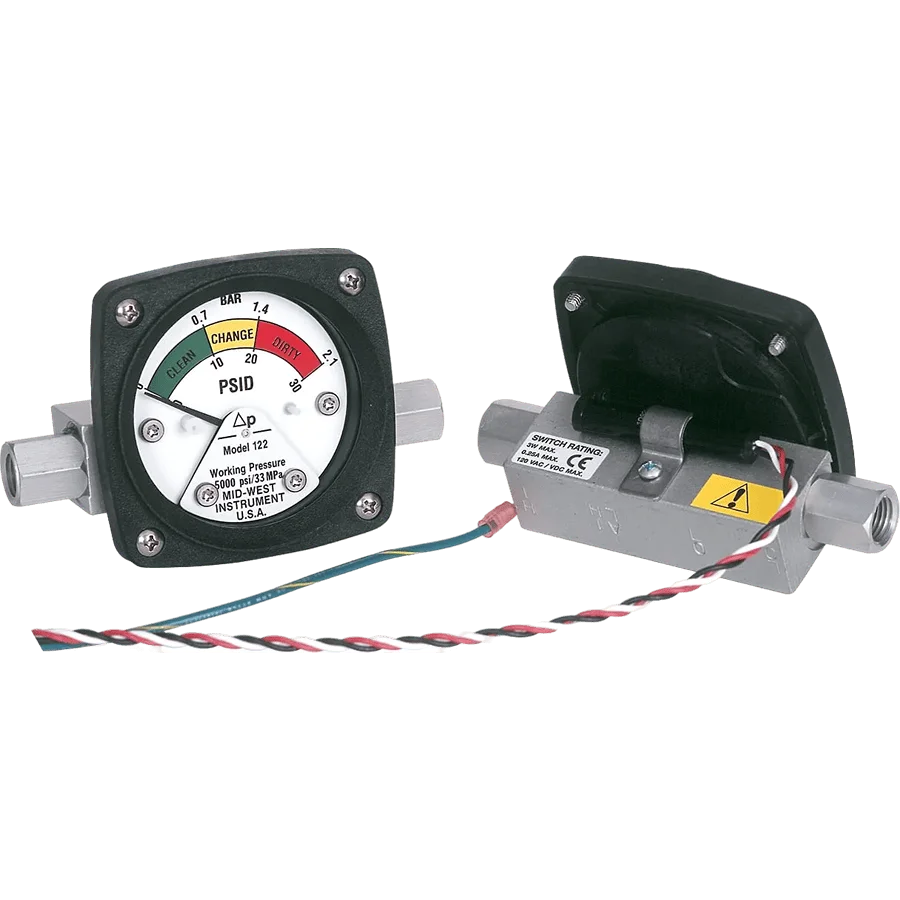

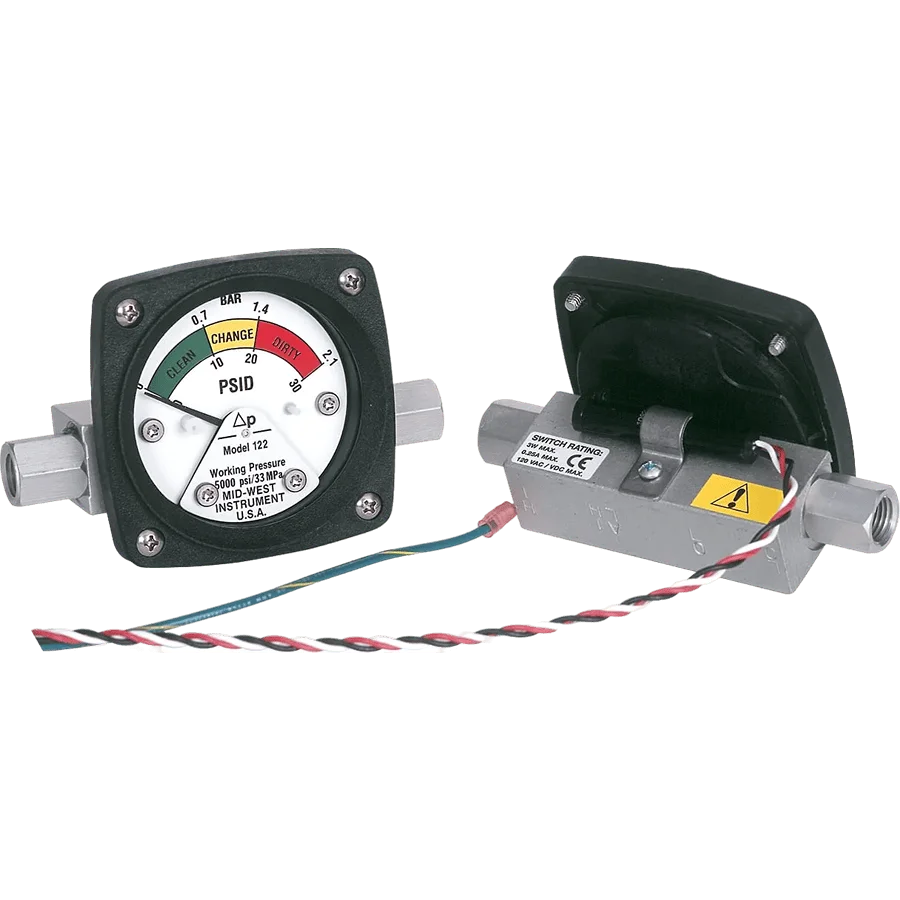

Model 122 Electrical Switch

Product Features and Benefits

- Most affordable entry-level piston gauge in the Model 120 series, delivering excellent performance with ±5% full-scale accuracy (ASME B40.1 Grade D)

- Rugged, compact, piston-type design with magnetically coupled internal piston and external rotary pointer for differential pressure indication

- Weather-resistant construction standard; NEMA 4X rating with shatter-resistant acrylic lens and engineered plastic dial case; anodised aluminum dial case option available

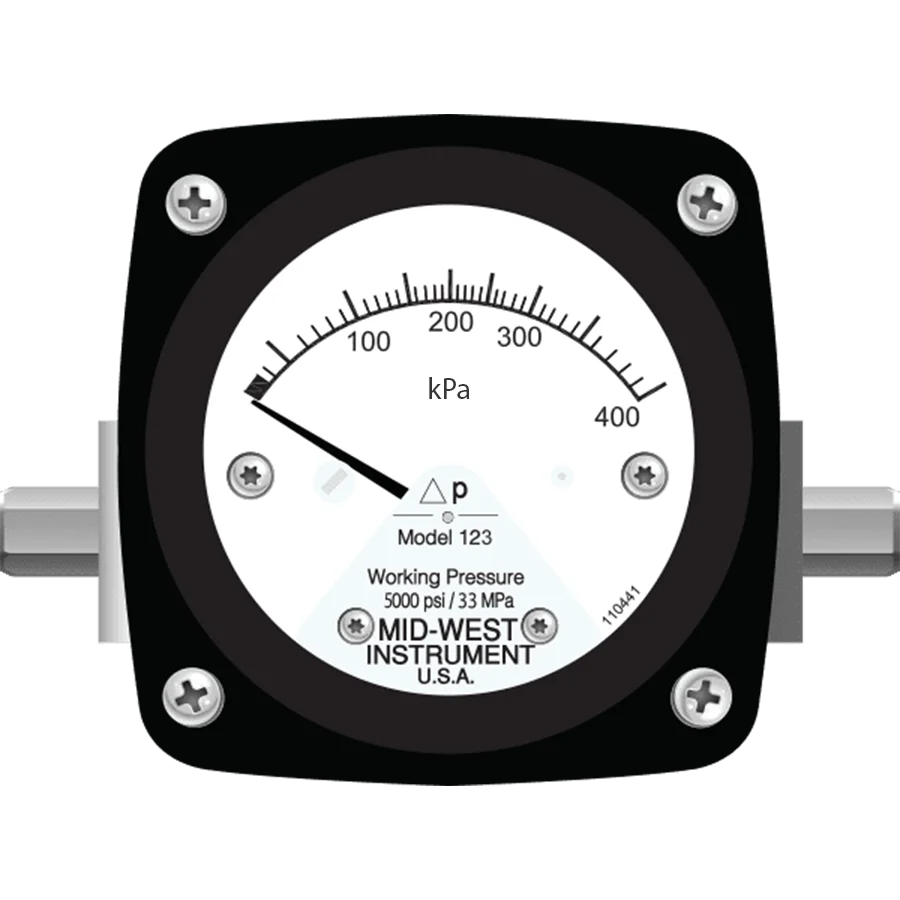

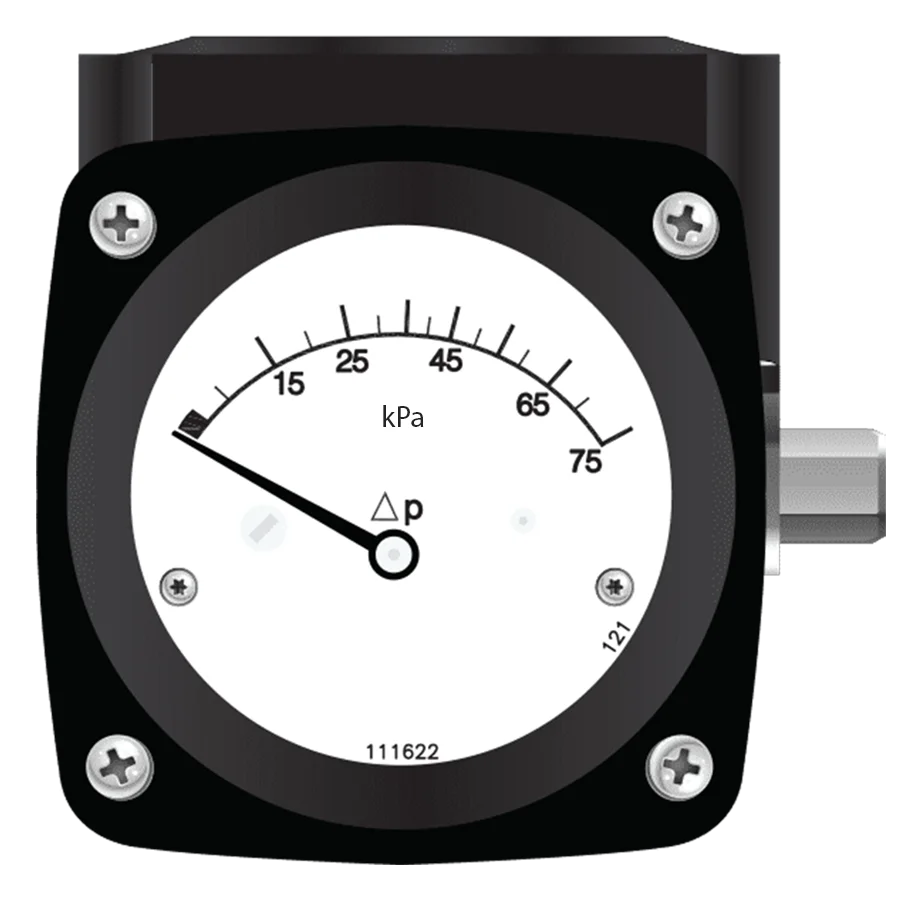

- Available dial sizes: 2½”, 3½”, 4½”, and 6” diameters with a wide variety of dial scale options including PSID, bar, kPa, dual scale, and other custom scales

- Working pressure up to 3,000 PSIG (200 bar) with over-range protection to maximum pressure

- Operating temperature range: -40°F to +200°F (-40°C to +93°C)

- ¼” FNPT end mounted process connection for ease of installation

- Seal elastomers include Buna-N, Viton®, Neoprene, Teflon®, and Ethylene Propylene for compatibility with various fluids and environments

- Optional clamp-on electrical switch configurations: one or two hermetically sealed reed switches with adjustable set points and multiple contact ratings

- Switch options CE/UKCA marked and RoHS compliant

- Optional features include reversed high/low process connections, liquid fill (glycerin or silicone), maximum indicator follower pointer, oxygen cleaning, stainless steel tags, wall mount kits, and specialised custom options

- Five year limited warranty

Model 122 is Mid-West Instrument’s most affordable entry-level piston type differential pressure gauge, offering reliable performance with a combined full-scale ascending accuracy of ±5% and differential pressure dial scales ranging from 0-5 PSID to 0-110 PSID (0.35 bar to 7.0 bar). Designed for ruggedness and simplicity, Model 122 delivers excellent value for applications requiring economical and dependable differential pressure measurement with optional clamp-on electrical switches.

DP Range And Accuracy

DP Range: 0-5 PSID to 0-100 PSID (0-0.35 bar to 0-7.0 bar)

as standard.

Other specialised ranges and scales available on request.

Full scale ascending accuracy ±5% for the differential gauge.

Leakage across piston does not exceed 32 SCFH air at 100 PSID at ambient conditions due to precision ground piston and bore.

as standard.

Other specialised ranges and scales available on request.

Full scale ascending accuracy ±5% for the differential gauge.

Leakage across piston does not exceed 32 SCFH air at 100 PSID at ambient conditions due to precision ground piston and bore.

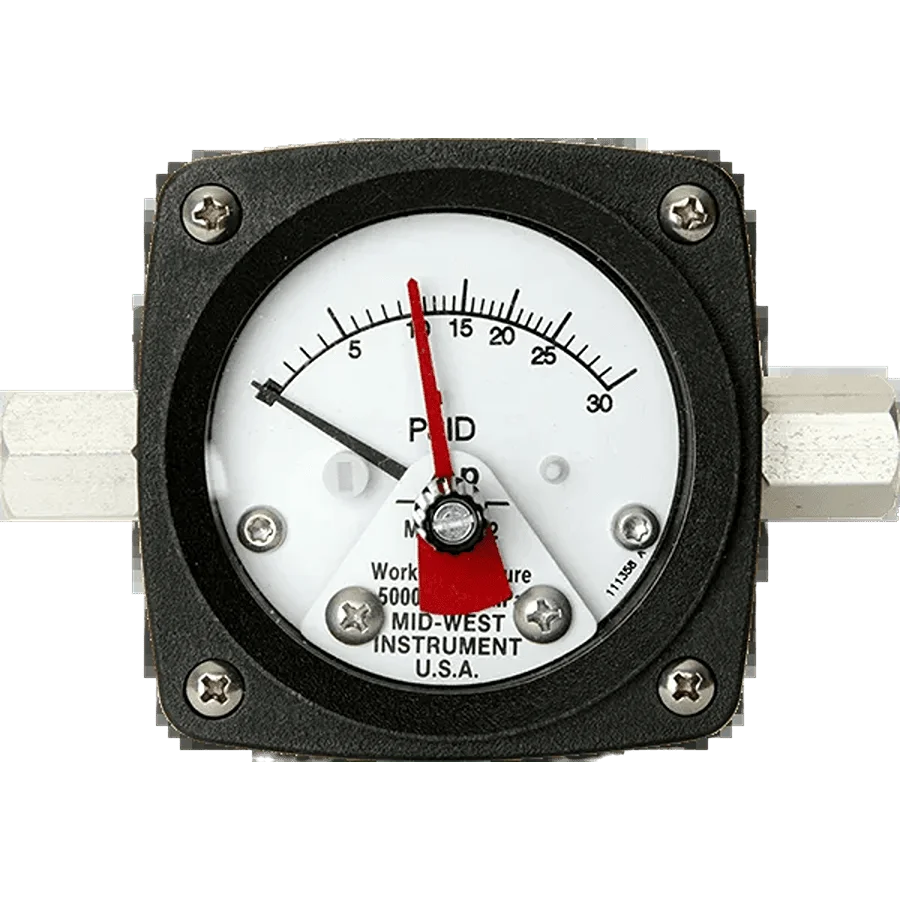

Model 122 With Follower Pointer

Model 122 in 4.5 Inch Dial

Common Applications

- Filter and strainer pressure drop monitoring

- Compressed air systems

- Hydraulic systems

- Refrigerant systems

- Pump performance testing

- Heat exchanger pressure drop monitoring

- Local flow indication and control

Additional Options

- Reversed high/low process connections

- Two 1/4-20 mounting holes

- Liquid fill (glycerin standard), silicone fill available (not compatible with shatterproof glass lens)

- Maximum indicator follower pointer (not available with 3½” and 6” dials or liquid fill)

- Shatter-proof glass lens (4½” dial only with aluminum dial case, not available with liquid fill)

- Oxygen cleaning

- Stainless steel tags with wire or screw attachment

- Wall mount kit

- Special un-coded options for customised configurations

ASME B1.20.1

ASME B40.100

NACE MR0175

NEMA Std. No. 250

CSA C22.2 No. 14, 25 and 30

SAE J514

EN-61010-1

UL Std. No. 50, 508 and 1203

ASME B40.100

NACE MR0175

NEMA Std. No. 250

CSA C22.2 No. 14, 25 and 30

SAE J514

EN-61010-1

UL Std. No. 50, 508 and 1203

Model 122

Additional Services

Custom Dial Face

Personalised dial faces tailored to your specifications.

Tagging Service

Services include stainless steel tags with wire or screw options.

Calibration Report

Calibration and accuracy certification from Mid-West or CMC.

Modification Service

Modification of existing stock units to for specific dial and electrical requirements.