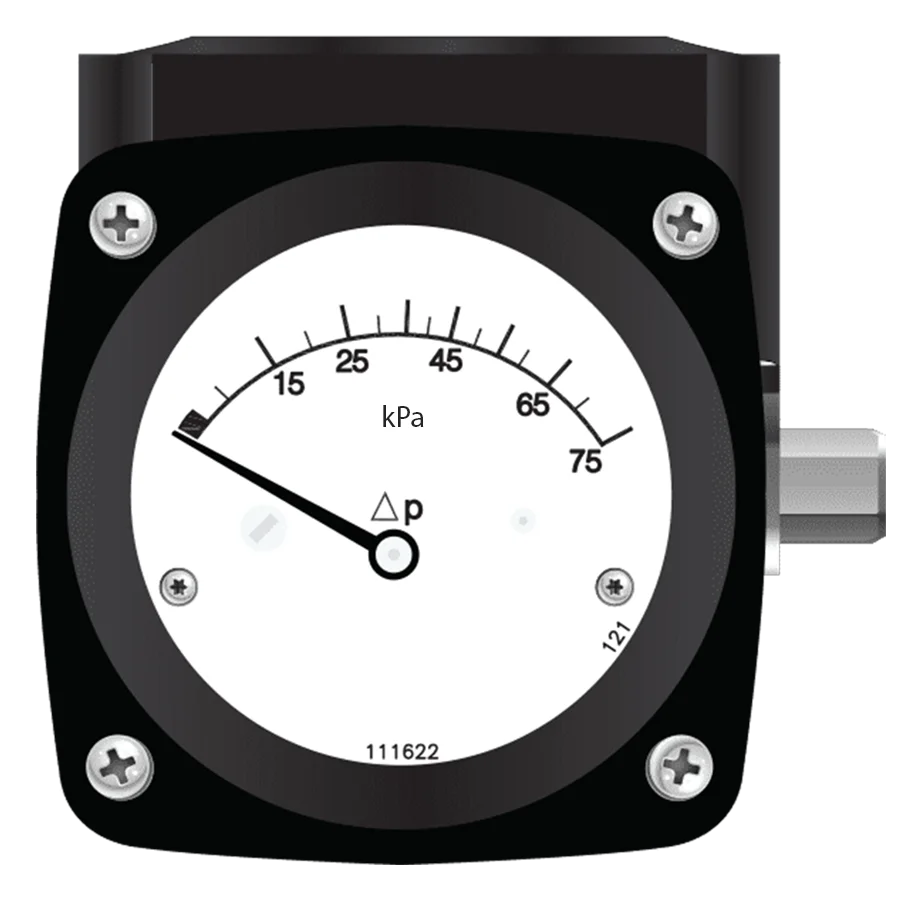

Model 121 Piston Type Differential Pressure Gauge & Switch

Aluminium Body and Stainless Steel Body

121-AA-00-OO

3,000 P.S.I.G. Working Pressure, aluminium body, adjusting screws & end plugs, stainless steel piston, ceramic magnet, Buna‑N seals, 2½” round dial, ¼” FNPT back connections, engineered plastic dial case with shatter‑resistant acrylic lens, ½” NPT conduit connection with NEMA 4X/IP65 switch/transmitter cover & terminal strip. Accuracy ±3/2/3% F.S.* (Ascending)

121-SA-00-OO

6,000 P.S.I.G. Working Pressure, 316L S.S. body, adjusting screws & end plugs, stainless steel piston, ceramic magnet, Buna‑N seals, 2½” round dial, ¼” FNPT back connections, engineered plastic dial case with shatter‑resistant acrylic lens, ½” NPT conduit connection with NEMA 4X/IP65 switch/transmitter cover & terminal strip. Accuracy ±3/2/3% F.S.* (Ascending)

Other Body Material: Monel & Aluminium Bronze Body Types are available (special order)

*Full Scale

3,000 P.S.I.G. Working Pressure, aluminium body, adjusting screws & end plugs, stainless steel piston, ceramic magnet, Buna‑N seals, 2½” round dial, ¼” FNPT back connections, engineered plastic dial case with shatter‑resistant acrylic lens, ½” NPT conduit connection with NEMA 4X/IP65 switch/transmitter cover & terminal strip. Accuracy ±3/2/3% F.S.* (Ascending)

121-SA-00-OO

6,000 P.S.I.G. Working Pressure, 316L S.S. body, adjusting screws & end plugs, stainless steel piston, ceramic magnet, Buna‑N seals, 2½” round dial, ¼” FNPT back connections, engineered plastic dial case with shatter‑resistant acrylic lens, ½” NPT conduit connection with NEMA 4X/IP65 switch/transmitter cover & terminal strip. Accuracy ±3/2/3% F.S.* (Ascending)

Other Body Material: Monel & Aluminium Bronze Body Types are available (special order)

*Full Scale

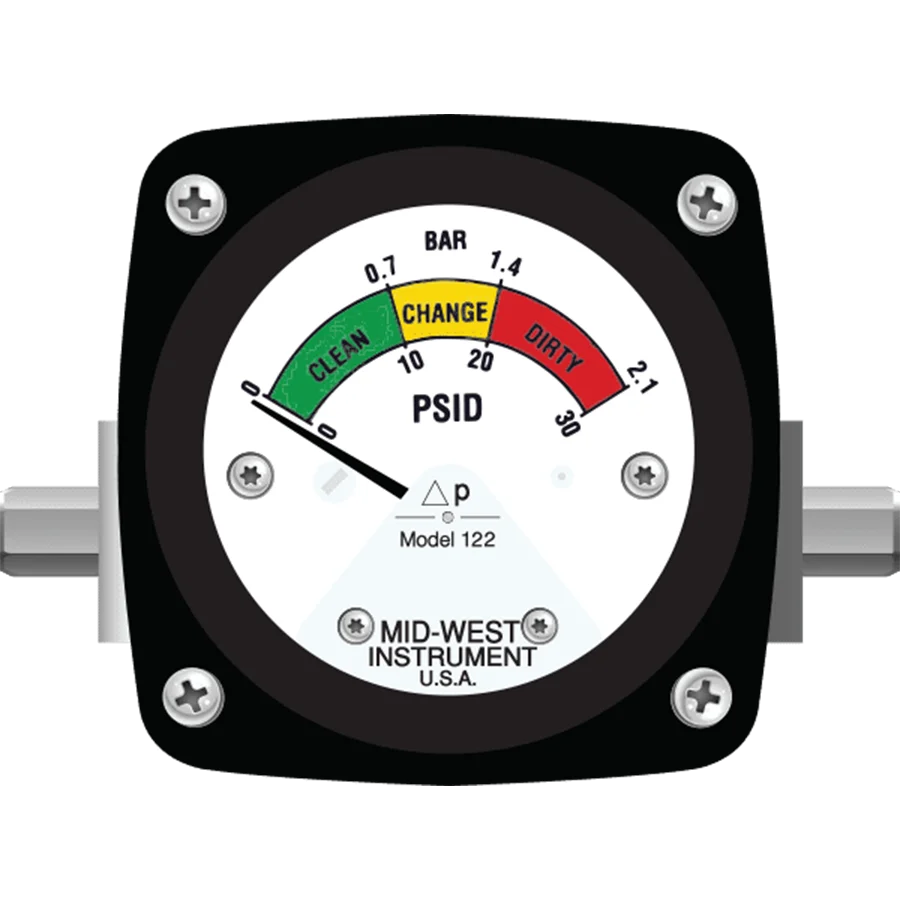

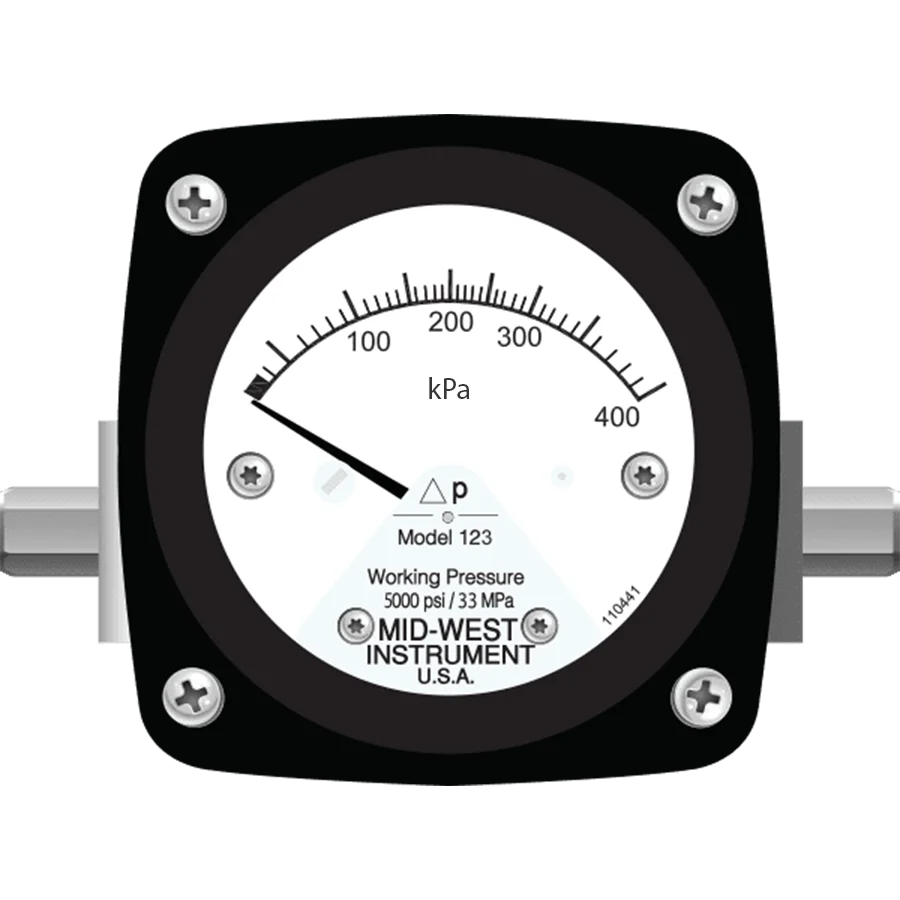

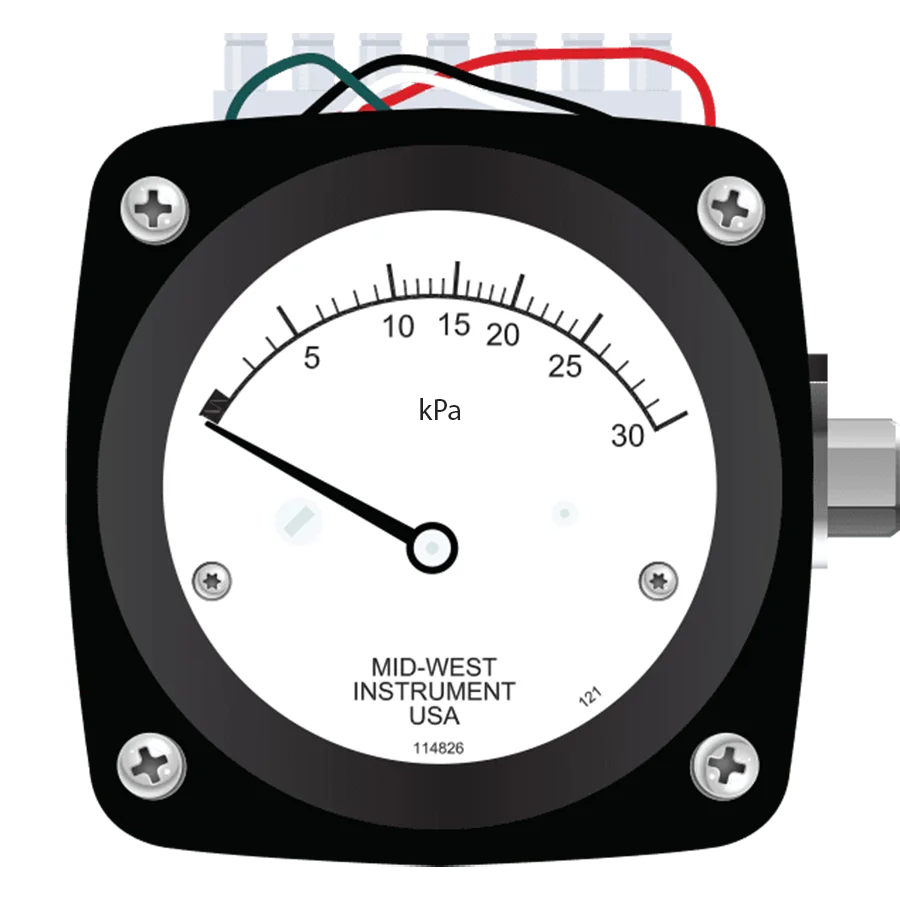

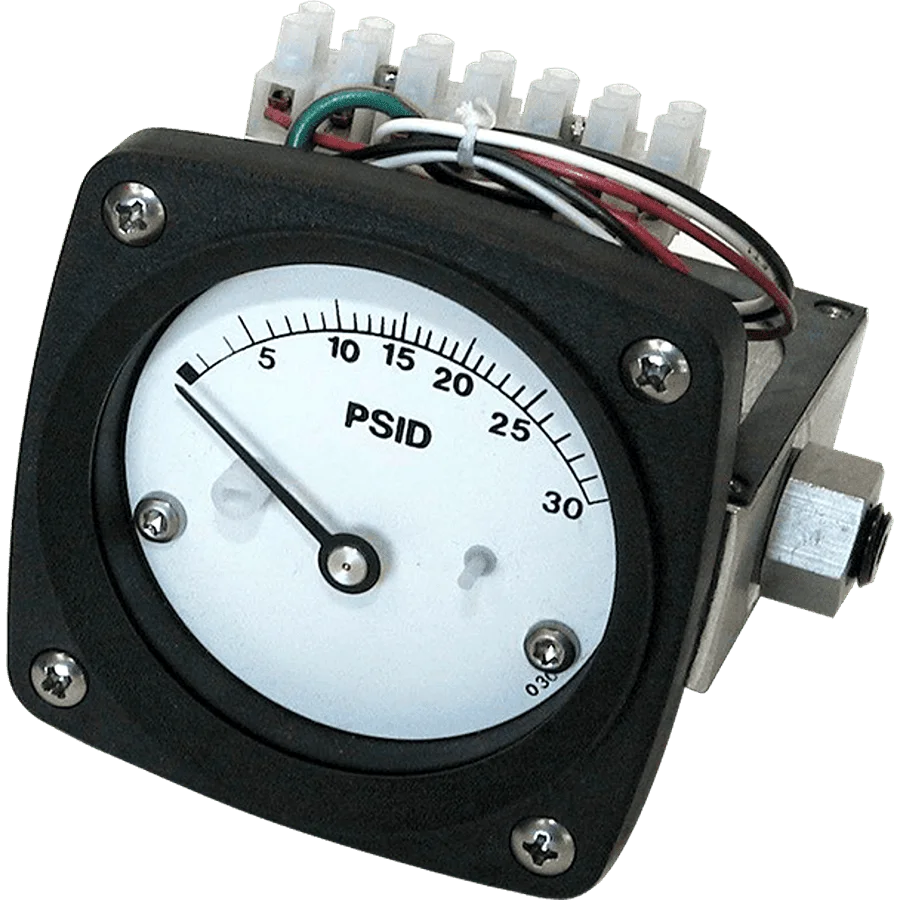

Model 121 2.5 Inch Dial

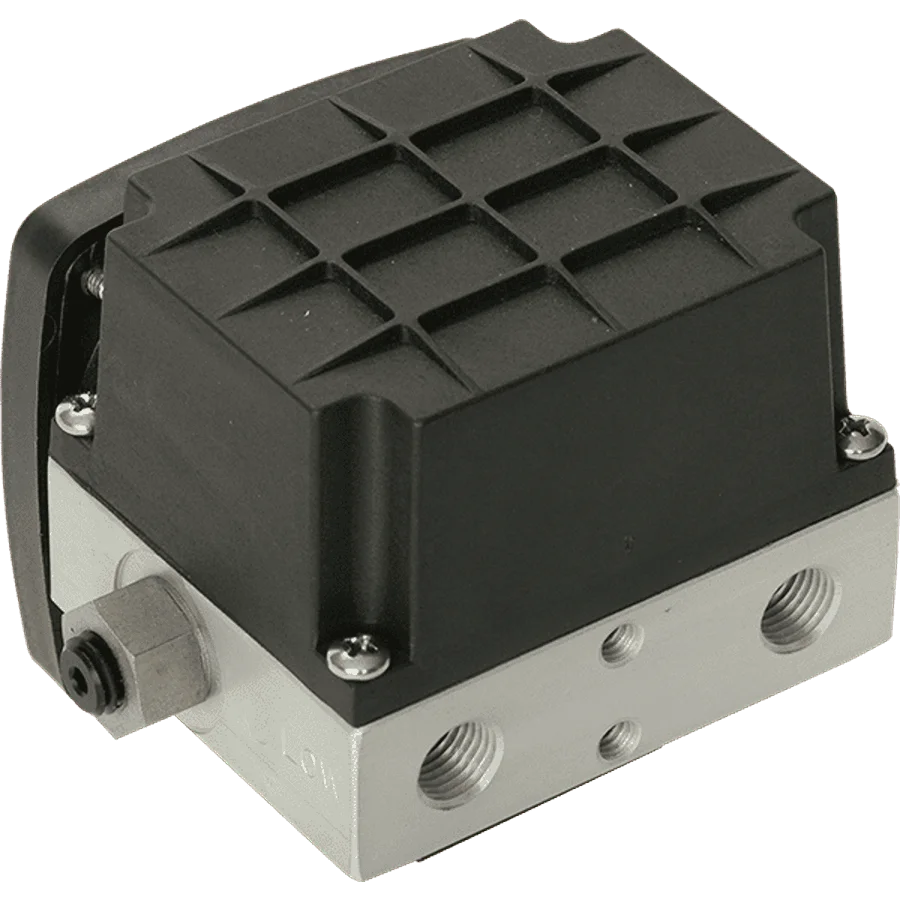

Model 121 Electrical Enclosure

Product Features and Benefits

- Low cost, rugged piston‑type DP switch and transmitter for reliable local indication and control.

- ½” NPT conduit connection with heavy‑duty switch/transmitter cover and terminal strip.

- Choice of 1 or 2 magnetically actuated hermetically sealed reed switches (adjustable set points).

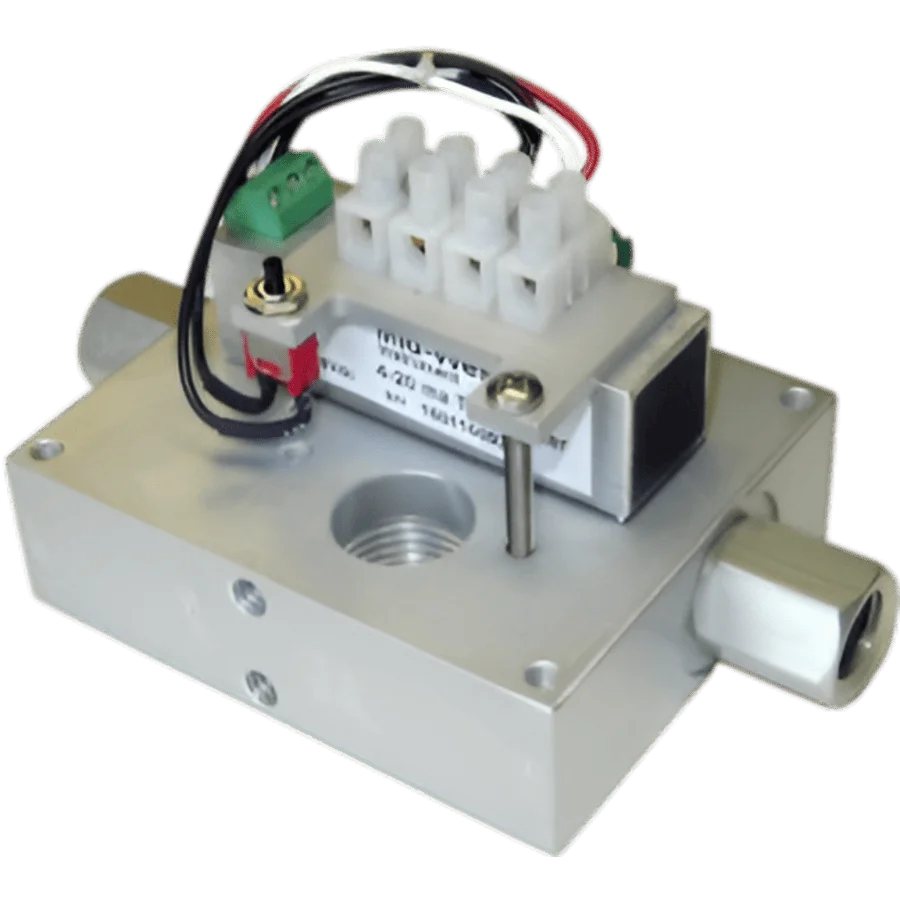

- Optional microprocessor‑based 4–20 mA transmitter (2‑wire loop) for remote monitoring.

- Weather‑resistant construction standard; NEMA 4X / IP65.

- Shatter‑resistant acrylic lens; engineered plastic dial case standard.

- Over‑range protection to maximum pressure.

- Operating Temp: Switch Options −40°F to +200°F (−40°C to +93°C); Transmitter Options −20°F to +150°F (−29°C to +66°C).

- Five year Limited Manufacturer Warranty on request.

Model 121 differential pressure gauges are designed to measure pressure drop across filters, strainers, separators, valves, pumps, chillers and heat exchangers, and for local flow indication and control. Differential pressure is sensed by the movement of a precisely ground floating piston/magnet in a precision bore; an external rotary pointer magnet follows the internal magnet to indicate differential pressure on the dial.

DP Range And Accuracy

DP Range: 0–5 PSID (0–0.35 bar) thru 0–100 PSID (0–7.0 bar)

Model 121 combined full‑scale ascending accuracy ±3/2/3% F.S.* (as shown in the standard model sequence). Transmitter accuracy: ±2% F.S. (from 20% to 100% of scale, ascending). Piston type gauges are primarily designed for liquid applications. Piston‑type DP gauges exhibit slight bypass as fluid crosses from the high to low pressure port; leakage across the piston will not exceed 32 SCFH air at 100 PSID at ambient conditions.

* Full Scale

Model 121 combined full‑scale ascending accuracy ±3/2/3% F.S.* (as shown in the standard model sequence). Transmitter accuracy: ±2% F.S. (from 20% to 100% of scale, ascending). Piston type gauges are primarily designed for liquid applications. Piston‑type DP gauges exhibit slight bypass as fluid crosses from the high to low pressure port; leakage across the piston will not exceed 32 SCFH air at 100 PSID at ambient conditions.

* Full Scale

Model 121

Model 121 in PSI Dial

Common Options

DP Ranges: Inches H2O, PSID, kPa, Bar, Dual Scale

Body Materials: Aluminum or 316L Stainless Steel (other alloys available special order)

Dial Types: 2½”, 3½”, 4½” & 6” Round; Uni‑Directional & Bi‑Directional

Seals & Diaphragm Materials: Buna‑N, Viton, Neoprene, Teflon, Ethylene Propylene, Perfluoroelastomer (optional)

Process Connections: ¼” FNPT back/end/bottom; ½” FNPT end; 7/16″‑20 straight thread O‑ring port

Mounting Kits: Carbon or Stainless Steel 2″ Pipe Mount Kit; Wall Mount Kit (consult factory for compatibility)

Liquid Fill or Maximum Follower Pointer (cannot combine)

Reversed high/low process connections, oxygen cleaning, stainless steel tags

Body Materials: Aluminum or 316L Stainless Steel (other alloys available special order)

Dial Types: 2½”, 3½”, 4½” & 6” Round; Uni‑Directional & Bi‑Directional

Seals & Diaphragm Materials: Buna‑N, Viton, Neoprene, Teflon, Ethylene Propylene, Perfluoroelastomer (optional)

Process Connections: ¼” FNPT back/end/bottom; ½” FNPT end; 7/16″‑20 straight thread O‑ring port

Mounting Kits: Carbon or Stainless Steel 2″ Pipe Mount Kit; Wall Mount Kit (consult factory for compatibility)

Liquid Fill or Maximum Follower Pointer (cannot combine)

Reversed high/low process connections, oxygen cleaning, stainless steel tags

Additional Options

Dial housing: Anodised aluminium dial case option available

Electrical: 1 & 2 switch standard; 4–20 mA transmitter option in NEMA 4X/IP65 enclosure; Division 2 hazardous location assemblies available (complete assembly 3rd party certified where specified)

Other: NACE compliance, CRN (Canadian Registration Number), factory preset switch set points at no charge

ASME B1.20.1

ASME B40.100

CSA‑C22.2 No. 14, 25 and 30

NACE MR0175 / ISO 15156

NEMA Std. No. 250

SAE J514

EN‑61010‑1

UL Std. No. 50, 508 and 1203

Electrical: 1 & 2 switch standard; 4–20 mA transmitter option in NEMA 4X/IP65 enclosure; Division 2 hazardous location assemblies available (complete assembly 3rd party certified where specified)

Other: NACE compliance, CRN (Canadian Registration Number), factory preset switch set points at no charge

ASME B1.20.1

ASME B40.100

CSA‑C22.2 No. 14, 25 and 30

NACE MR0175 / ISO 15156

NEMA Std. No. 250

SAE J514

EN‑61010‑1

UL Std. No. 50, 508 and 1203

Model 121 Transmitter

Additional Services

Custom Dial Face

Personalised dial faces tailored to your specifications.

Tagging Service

Services include stainless steel tags with wire or screw options.

Calibration Report

Calibration and accuracy certification from Mid-West or CMC.

Modification Service

Modification of existing stock units to for specific dial and electrical requirements.