www.dpgauges.com.au - CMC Technologies Pty Limited

Unit 19, 77 Bourke Road ,

Alexandria ,

NSW 2015

Australia

Tel: +61 2 9669 4000

Fax: +61 2 9669 4111 |

|

Mid-West Instrument Bourdon Tube - type Differential Pressure Gauge/Switch 109 | |

| |

Mid-West Instrument Model 109 Bourdon Tube Differential Pressure Gauge |

| |

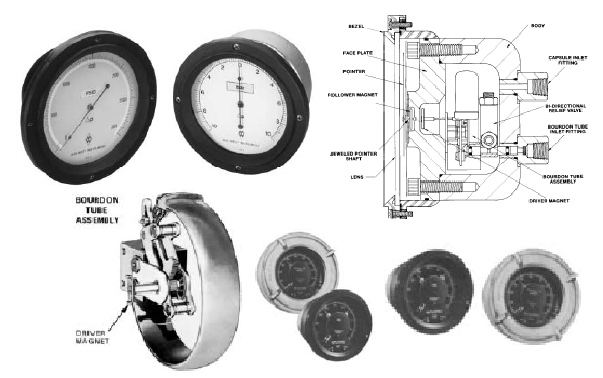

| The Model 109 encapsulated bourdon tube design provides a simple, compact, and accu-rate differential pressure indicator. The Model 109 is powered by a test quality Bourdon Tube assembly.The assembly is encapsulated in ahigh pressure chamber that is fitted with a pressure connection to the inside of the Bourdon Tube and a sec-ond connection to the pressure chamber.

The model 109 indicates the difference between the pressure applied inside the Bourdon Tube and the pressure inside the chamber.The pressure chamber for the assembly is small, close fitting and rugged.The volume displacement of the Bourdon Tube through the pressure range is near to zero (0.02 c.c.).The speed of response of the indicatorto changes in differential pressure is instantaneous, even on low volume pressure systems.The low volume displacement is an important advantage for differential pressure leakdetection, and when isolation diaphragms are required.The Bourdon Tube Assembly is protected against overrange in either direction to the rated working pressureby a bi-directional relief valve.The output shaft of the gauge assembly is magnetically coupled through the solid wall of the pressure chamber to a sensitive jeweled pointershaft in the dial housing outside the chamber.The magnetic coupling transmits the exact motion of the assembly to the pointer to give an accurate dialreading of the differential pressure.

The Bourdon Tube is mounted on a connection block and to an open gearand sector gauge movement.A ceramic coupling magnet is carried on theoutput shaft of the movement. A bi-directional relief valve is installed between the Bourdon Tube assemblyand the high pressure inlet port.

The gauge assembly is a bolted sealed pressure chamber witha solid face plate and a heavy walled capsule.The assembly israted at 1500, 3000 or 6000 P.S.I.G.working pressure.Pressure connections are located on the back of the capsule.The indicating mechanism of the model 109 (the pointer, hand-staff, and dial) is in a corrosion resistant engineering plastic case bolted and sealed to the face plate of the pressure chamber.The pointer is carried on a shaft with jeweled bearings.The dial, silk screened on mirrored band aluminum, is designed so it maybe rotated underneath the pointer, should re-zeroing be necessary.

The shatter resistant acrylic lens is permanently attached to the bezel which snaps on to the gauge case and is sealed by aresilient seal.It is mounted to the dial chamber by four screws.

|

| |

|

| UPC code: | M35 |

|

| Manufactured by: | Mid-West Instrument |

|

| Made in USA |

| Payment Methods |

| Cheque or Direct Bank / Telegraphic Transfer |

|

|

| Ref | |

| Description | Mid-West Instrument Bourdon Tube - type Differential Pressure Gauge/Switch 109 |

|

|

|

|