Model 140 Diaphragm Type Differential Pressure Gauge & Switch

Aluminium, Brass and Stainless Steel Body

140-AA-00-OO

3000 P.S.I.G. Working pressure, aluminum body, 316L stainless steel internal metal parts, ceramic magnets, Buna-N diaphragm and seals, Teflon guide bushings, 2½” round dial, ¼” FNPT back connections, engineered plastic gauge case with shatter-resistant acrylic lens. Accuracy ±5% F.S. (0-50″ H2O to 0-399″ H2O) and ±3/2/3% F.S.* (0-15 PSID to 0-100 PSID) (Ascending).

140-BA-00-OO

3000 P.S.I.G. Working pressure, brass body, 316 stainless steel internal metal parts, ceramic magnets, Buna-N diaphragm and seals, Teflon guide bushings, 2½” round dial, ¼” FNPT back connections, engineered plastic gauge case with shatter-resistant acrylic lens. Accuracy ±5% F.S.* (0-50″ H2O to 0-399″ H2O) and ±3/2/3% F.S. (0-15 PSID to 0-100 PSID) (Ascending).

140-SA-00-OO

3000 P.S.I.G. Working pressure, 316/316L S.S. body, 316 stainless steel internal metal parts, ceramic magnets, Buna-N diaphragm and seals, Teflon guide bushings, 2½” round dial, ¼” FNPT back connections, engineered plastic gauge case with shatter-resistant acrylic lens. Accuracy ±5% F.S. (0-50″ H2O to 0-399″ H2O) and ±3/2/3% F.S. (0-15 PSID to 0-100 PSID) (Ascending).

Other Body Materials: Aluminum Bronze & Monel Body Types are also available

3000 P.S.I.G. Working pressure, aluminum body, 316L stainless steel internal metal parts, ceramic magnets, Buna-N diaphragm and seals, Teflon guide bushings, 2½” round dial, ¼” FNPT back connections, engineered plastic gauge case with shatter-resistant acrylic lens. Accuracy ±5% F.S. (0-50″ H2O to 0-399″ H2O) and ±3/2/3% F.S.* (0-15 PSID to 0-100 PSID) (Ascending).

140-BA-00-OO

3000 P.S.I.G. Working pressure, brass body, 316 stainless steel internal metal parts, ceramic magnets, Buna-N diaphragm and seals, Teflon guide bushings, 2½” round dial, ¼” FNPT back connections, engineered plastic gauge case with shatter-resistant acrylic lens. Accuracy ±5% F.S.* (0-50″ H2O to 0-399″ H2O) and ±3/2/3% F.S. (0-15 PSID to 0-100 PSID) (Ascending).

140-SA-00-OO

3000 P.S.I.G. Working pressure, 316/316L S.S. body, 316 stainless steel internal metal parts, ceramic magnets, Buna-N diaphragm and seals, Teflon guide bushings, 2½” round dial, ¼” FNPT back connections, engineered plastic gauge case with shatter-resistant acrylic lens. Accuracy ±5% F.S. (0-50″ H2O to 0-399″ H2O) and ±3/2/3% F.S. (0-15 PSID to 0-100 PSID) (Ascending).

Other Body Materials: Aluminum Bronze & Monel Body Types are also available

Model 140 2.5 Inch Dial

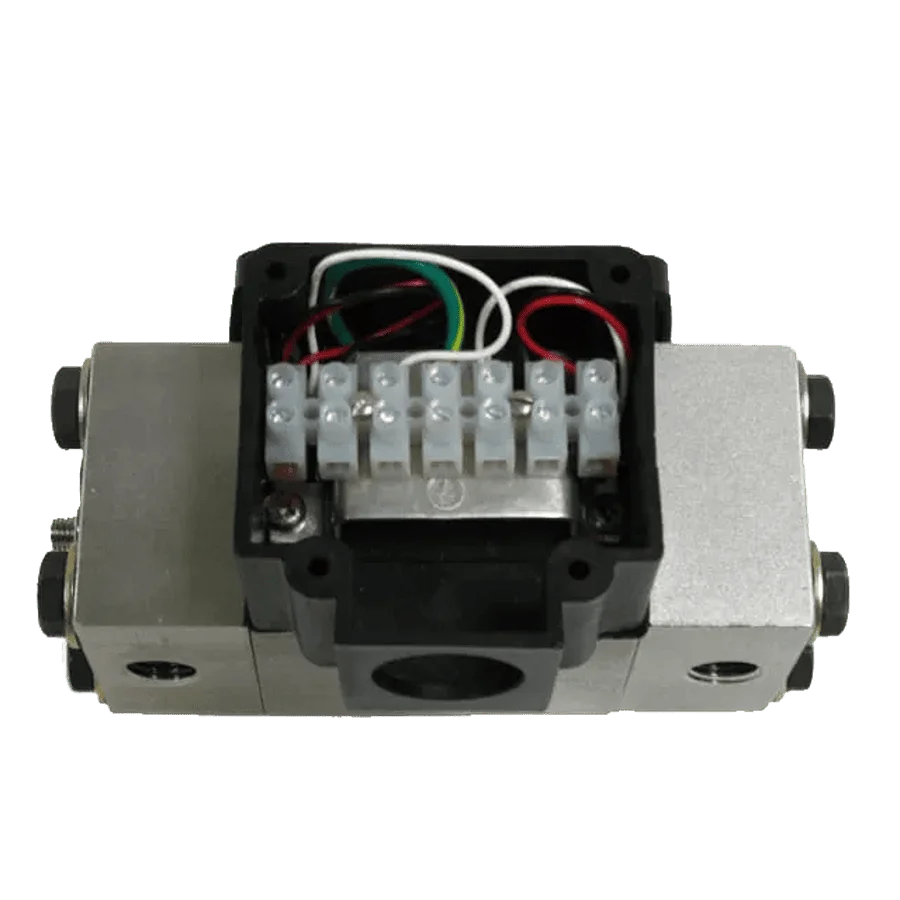

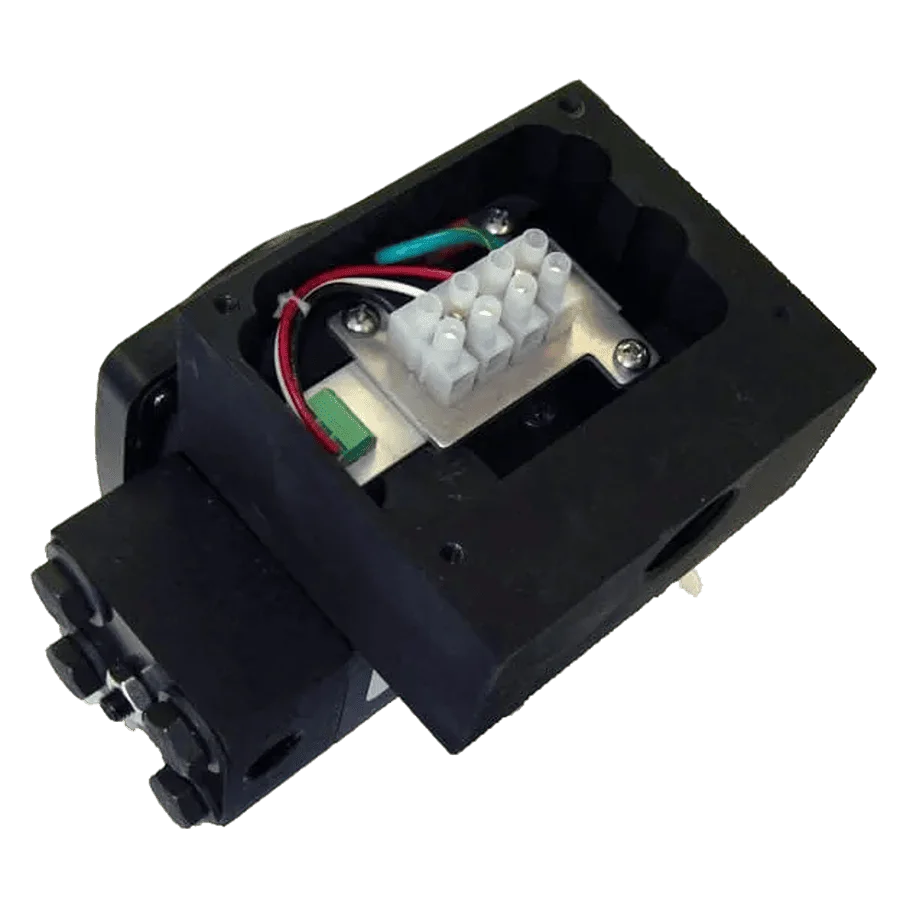

Model 140 Electrical Enclosure

Product Features and Benefits

- Rugged Convoluted Diaphragm Design with no cross port leakage.

- Glass Reinforced Thermoplastic Dial Case (Panel Mountable) with anodized aluminum dial case option available.

- Terminal Strip Interface to aid in ease of electrical installation of switch or transmitter.

- Over-range protection, High over Low and Low over High.

- Weather Resistant & Corrosion Resistant rated to NEMA 4X/IP65.

- Shatter Resistant Lens

- Operating Temp. -40° F to +200° F (-40°C to +93°C)

- 4-20 mA Transmitter Option for applications requiring constant monitoring.

- Multiple Switch Options including Hazardous location options.

- Five year Limited Warranty on every gauge.

Mid-West differential pressure gauges are designed to measure pressure drop across Filters, Strainers, Separators, Valves, Pumps, Chillers, Heat Exchangers, etc. as well as for tank level monitoring and flow indication and control. The Model 140 is an accurate and versatile diaphragm type differential pressure gauge/switch or transmitter that will meet your most demanding DP requirements.

DP Range And Accuracy

DP Range: 0-50″ H2O to 0-100 PSID (0-125 mbar to 0-7.0 bar)

Mid-West Diaphragm Type: Model 140 ±5% Full Scale Accuracy (0-50″ H2O to 0-399″ H2O) and ±3/2/3% Full Scale Accuracy (0-15 PSID to 0-100 PSID). Diaphragm type gauges are designed for both liquid and gas applications. Differential Pressure is sensed by a rugged convoluted elastomer diaphragm sensing element that provides no cross port leakage. The diaphragm responds to pressure differentials and transmits this movement through a magnetic coupling system to the external pointer mechanism, indicating differential pressure on the dial. The convoluted design ensures reliable operation and eliminates the slight bypass characteristic of piston type gauges.

Mid-West Diaphragm Type: Model 140 ±5% Full Scale Accuracy (0-50″ H2O to 0-399″ H2O) and ±3/2/3% Full Scale Accuracy (0-15 PSID to 0-100 PSID). Diaphragm type gauges are designed for both liquid and gas applications. Differential Pressure is sensed by a rugged convoluted elastomer diaphragm sensing element that provides no cross port leakage. The diaphragm responds to pressure differentials and transmits this movement through a magnetic coupling system to the external pointer mechanism, indicating differential pressure on the dial. The convoluted design ensures reliable operation and eliminates the slight bypass characteristic of piston type gauges.

Model 140 4.5 Inch Dial

Model 140 Follower Pointer

Common Options

DP Ranges: PSID, Bar, Mbar, kPa, Kg/Cm², Dual Scale

Body Materials: Aluminum, Brass, 316/316L Stainless Steel, Aluminum Bronze & Monel

Dial Types: 2½”, 3½”, 4½” and 6″ Round Diameters available

Seals & Diaphragm Materials: Buna-N, Viton, Silicone, Neoprene, Ethylene Propylene

Connections: ¼” FNPT Back Connections (Multiple process connection sizes and locations available)

Switch Options: 1 or 2 Independent adjustable switches, SPDT 3W (0.25 Amp, 125 VAC/VDC), SPST 25W (0.5 Amp, 230 VAC/VDC Normally Open)

Transmitter Option: 4-20 mA, 2-wire loop powered, microprocessor based, 2% accuracy (20%-100% of scale)

Body Materials: Aluminum, Brass, 316/316L Stainless Steel, Aluminum Bronze & Monel

Dial Types: 2½”, 3½”, 4½” and 6″ Round Diameters available

Seals & Diaphragm Materials: Buna-N, Viton, Silicone, Neoprene, Ethylene Propylene

Connections: ¼” FNPT Back Connections (Multiple process connection sizes and locations available)

Switch Options: 1 or 2 Independent adjustable switches, SPDT 3W (0.25 Amp, 125 VAC/VDC), SPST 25W (0.5 Amp, 230 VAC/VDC Normally Open)

Transmitter Option: 4-20 mA, 2-wire loop powered, microprocessor based, 2% accuracy (20%-100% of scale)

Additional Options

Mounting Options: Pipe Mounting Kit (2″ U-Bolt), Wall Mounting Kit, ¼-20 Mounting Holes in back of gauge body

Performance Options: Liquid Fill, Maximum Follower Pointer, Oxygen Cleaning

Compliance: NACE Compliance, CRN – Canadian Registration Number (Aluminum and Stainless Steel Bodies only)

Hazardous Locations: Class I Division I (Groups C & D), Class II Division I (Groups E, F & G), Class I Division II (Groups A, B, C & D), Class II Division II (Groups F & G)

Electrical Enclosures: NEMA 4X and NEMA 7, Weather-Resistant NEMA 4X/IP66

All Model 140 differential pressure gauges either conform to and/or are designed to the requirements of the following standards:

ASME B40.1 (Grade D for 50″ H2O to 399″ H2O ranges, Grade B for 15 PSID to 100 PSID ranges)

CSA B51-09 SAI GLOBAL

CSA and UL Listing

CE Marked in Accordance With Low Voltage & RoHS Directives

NEMA Std. No. 250

Performance Options: Liquid Fill, Maximum Follower Pointer, Oxygen Cleaning

Compliance: NACE Compliance, CRN – Canadian Registration Number (Aluminum and Stainless Steel Bodies only)

Hazardous Locations: Class I Division I (Groups C & D), Class II Division I (Groups E, F & G), Class I Division II (Groups A, B, C & D), Class II Division II (Groups F & G)

Electrical Enclosures: NEMA 4X and NEMA 7, Weather-Resistant NEMA 4X/IP66

All Model 140 differential pressure gauges either conform to and/or are designed to the requirements of the following standards:

ASME B40.1 (Grade D for 50″ H2O to 399″ H2O ranges, Grade B for 15 PSID to 100 PSID ranges)

CSA B51-09 SAI GLOBAL

CSA and UL Listing

CE Marked in Accordance With Low Voltage & RoHS Directives

NEMA Std. No. 250

Model 140 Elec Enclosure

Additional Services

Custom Dial Face

Personalised dial faces tailored to your specifications.

Tagging Service

Services include stainless steel tags with wire or screw options.

Calibration Report

Calibration and accuracy certification from Mid-West or CMC.

Modification Service

Modification of existing stock units to for specific dial and electrical requirements.